Steam distribution systems

The CAREL range of accessories for isothermal humidifiers have been especially developed to allow the creation of humidification systems that are complete and suitable for all types of application.

The fundamental idea is to guarantee optimum operation of the humidification system by providing the installer, maintenance personnel and user all the auxiliary components that simplify installation, steam distribution, operation and control of the humidifier.

The new high-efficiency linear steam distributors are the first to feature thermal insulation so as to reduce condensation in the ducting.

This innovation brings extremely positive results in terms of energy efficiency: tests have in fact shown a reduction of at least 20% in condensation when compared to standard steam distributors.

These accessories are available for the humiSteam, compactSteam, heaterSteam and gaSteam humidifiers.

ultimateSAM

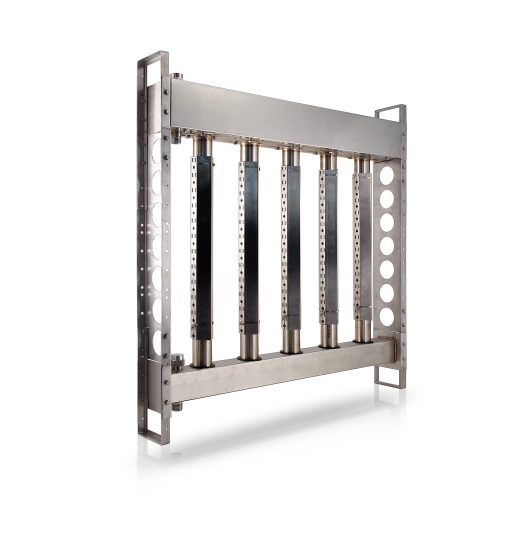

ultimateSAM is a distributor for both pressurised steam and steam at atmospheric pressure; in the latter case it can therefore be used together with Carel humidifiers. SAM stands for Short-Absorption Manifold, meaning a steam distributor with a short absorption distance (even less than 200 mm). It has been designed to be “made to measure” for the AHU or duct, while ensuring low air heat gain (max. 2 °C/4 °F). With the ultimateSAM compact version, the steam distributor can be installed even in smaller ducts.

All of the metal parts installed inside the AHU or duct are made from AISI 304 steel, so as to guarantee hygiene and a long operating life. The features of the ultimateSAM steam distribution system make it the perfect system for all AHU/duct humidification needs, providing designers, installers and service personnel with the best possible solution.

The wide range of products, with a vast choice of steam flow-rates and numerous options, make it the ideal system for various applications, including hospitals and the pharmaceutical industry.

AHU - High-efficiency steam distributors

These new steam distributors complete the current product range, thus providing a response to all customer needs, also in terms of energy savings.

The air cushion, acting as an insulator between the steam pipe and the outer jacket, reduces heat exchange between the hot steam inside the distributor and the lower-temperature air in the duct/AHU: this reduces condensation by at least 20%.

Just like in the other versions, excellent steam distribution is ensured by the modular construction, making it possible to virtually cover all duct/AHU widths and exploit as much air flow as possible.

The lengths range from 350 mm to 2050 mm, in 30 mm or 40 mm diameters.

Steam nozzles

Steam nozzles for distributing steam into small ducts or steam baths (SDPOEM0012 for models from 1 to 3 kg/h, SDPOEM0022 for models from 5 to 18 kg/h, SDPOEM0000).

Steam blowers

The steam blowers for rooms (VSDU0A0003) are suitable for humidifiers up to 18 kg/h. The steam blower can be fitted directly onto the humidifier, or in a remote position. In the latter case, a support is required for mounting the blower (VSDBAS0001), as well as a steam hose to connect the blower to the humidifier. The steam blower works in ON/OFF mode, and is controlled by a temperature device that is activated when steam is produced.

For humidifiers larger than 18 kg/h, the VRDXL00001 steam blowers are available, with 230 Vac power supply; these are designed for installation separately from the humidifier, and require two 40 mm diameter steam hoses.

The new generation of blowers guarantees:

- a steam absorption distance of around one metre, allowing the unit to be positioned in complete safety;

- a range of steam production modulation from 0 to 100%;

- backward compatibility with existing installations.